Embracing Construction Robotics: The Future of Construction Field Operations

On today’s construction sites, construction managers coordinate and supervise construction projects that include a team of hard-working construction professionals as well as construction equipment. In the months and years ahead, however, construction managers will be implementing advanced technology and incorporating construction robots on their projects.

What Is Construction Robotics?

Construction robotics refers to the use of robotic engineering within the construction industry, often to automate tasks and reduce the amount of manual labor that human workers have to perform. These technical advancements can increase the speed of construction projects, reduce errors, and enhance safety in the construction workforce.

Key Technologies in Construction Robotics

According to the Centers for Disease Control (CDC), automation in the construction industry is not a new concept, but the application of construction robotics is having a transformative impact on the industry. These are some of the key technologies in construction robotics:

Autonomous Mobile Robots (AMRs)

On construction sites, heavy and bulky materials often have to be relocated, which can be both dangerous and time-consuming. Autonomous mobile robots (AMR) have the ability to navigate complex environments and can be used for both material handling, load carrying, and site surveying.

Robotic Arms and Exoskeletons

Robotic arms and exoskeletons are becoming more common on modern construction sites, largely because of their versatility. They have the ability to automate simple tasks, such as welding or painting, freeing up human workers to take on more complex and creative tasks.

Drones and UAVs

Playing a key role in improving safety on construction sites, drones and unmanned aerial vehicles (UAVs) are often used by construction managers to survey the construction site and complete site inspections.

3D Printing Robots

Cartesian robots can be used for 3D printing, allowing construction managers and supervisors to create a wide range of 3D printed products that are available when needed and possibly more affordable.

AI-Powered Inspection Robots

AI-powered inspection robots are used to quickly and easily inspect construction equipment and construction sites. Equipped with cameras and advanced sensors, these robots automate the inspection process and have the capability of spotting errors or issues that human workers may miss.

How Robotics Is Transforming Construction Management

Automation has played a crucial role in construction management for years, but robotics is truly transforming the landscape for those responsible for developing, overseeing, and supervising construction projects.

- Project Planning and Design — Robotics is streamlining the planning and design process, with AI technology automating many of the planning tasks that project planners used to take on themselves.

- On-Site Productivity — By automating simple and repetitive tasks, human workers on construction sites can be more productive and efficient.

- Quality Control — Robotics technology can be used to survey and inspect construction progress, ultimately improving quality control efforts.

- Safety Enhancement — Robotics technology enhances safety and offers greater protection to the construction industry workforce by undertaking some of the most hazardous tasks.

- Data-Driven Decisions — With the capability to collect and interpret data in real-time, robotics technology can enable data-driven decision-making in construction management.

Benefits of Adopting Robotics in Construction Management

Construction companies will find that now is the best time to begin adopting and applying robotics technology to their projects. The leading benefits of AI-powered and robotics technology in construction include:

Increased Efficiency and Speed

Through automation, robotics technology is able to increase the efficiency and speed of construction projects, allowing construction managers to increase the opportunity for on-time, on-budget delivery by improving productivity overall.

Cost Reduction Over Time

While construction robotics require a significant financial investment, construction managers will quickly see that the increased efficiency offered by this technology allows them to lower costs over the long-term.

Improved Site Safety

Robotic technology is able to navigate complex landscapes and accomplish high-risk tasks, allowing construction managers to improve site safety overall.

Enhanced Precision and Consistency

Robotic technology enhances precision and consistency on construction sites, which improves the overall quality of work while allowing human workers to focus on more complex and nuanced tasks.

Labor Shortage Mitigation

The Association of Builders and Contractors reveals that more than 454,000 additional construction workers are needed to meet industry demand in 2025, defining the breadth and depth of the ongoing construction worker shortage. Robotic technology can be used to supplement human workers, which can alleviate some effects of the labor shortage.

Common Applications of Construction Robotics

Construction managers who prioritize construction technology and innovation will find that these common applications of construction robotics are available and particularly helpful:

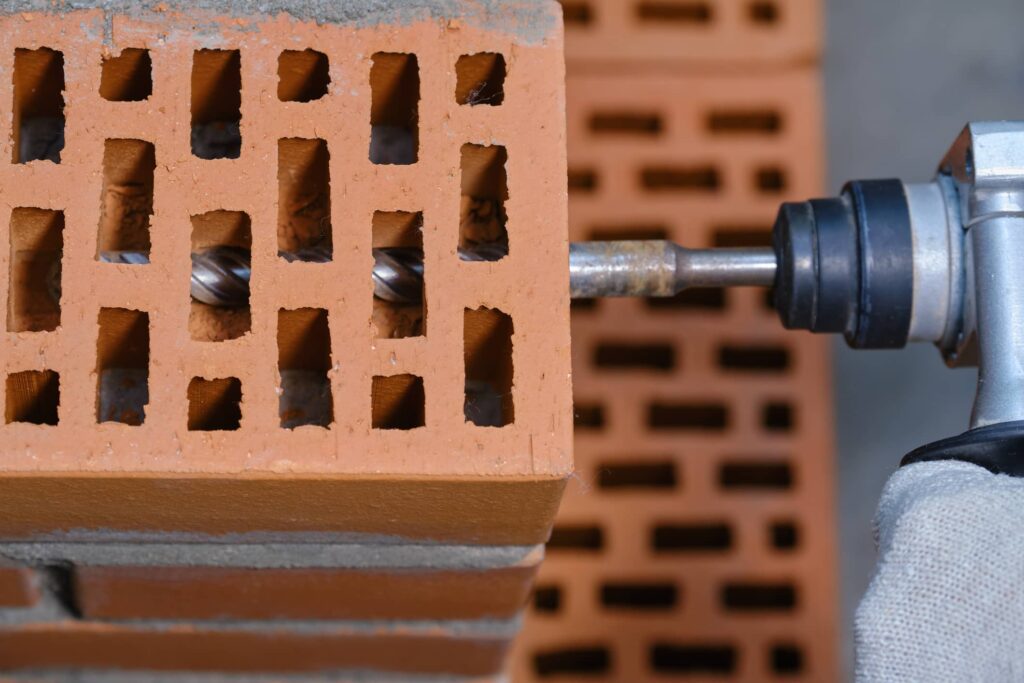

Bricklaying Robots

Bricklaying robots lay bricks at faster speeds than human workers, increasing efficiency and improving safety overall.

Rebar Tying

Vision-equipped robots can automate the rebar tying process, improving the structural strength of reinforced concrete and preventing human workers from taking on this strenuous and injurious task.

Robotic Welding

Robots are being used to automate welding on construction sites, with higher precision and higher productivity allowing for less rework and better quality.

Robotic 3D Printing

Robotic 3D printing allows construction managers to create lower-cost 3D printed products that can be used on the job site.

Demolition Robots

Remote-controlled demolition robots allow human workers to oversee site demolition from a safe distance without risking injury.

Site Inspection and Monitoring

Drones and UAVs are often used to inspect and monitor construction sites, improving the precision of inspection frequency while promoting safety on the construction site.

Challenges and Barriers to Adoption

While the leading construction robotics applications have the power to revolutionize the construction industry, there are some challenges that organizations should consider:

- High Initial Costs — Robotic systems are currently expensive, which may prevent some construction companies from investing in this technology.

- Skilled Workforce Requirement — The construction workforce needs training to use robotics technology, and there is currently a shortage of workers who have this knowledge in the industry.

- Resistance to Change — Traditional construction approaches have been in place for decades, with some workers feeling resistant to change and therefore unwilling to adapt accordingly.

- Interoperability Issues — Interoperability issues can prevent construction robotics technology from operating correctly or efficiently in the field.

- Regulatory and Safety Standards — Changing regulatory and safety standards can make it difficult to adopt new and innovative technology.

Case Studies: Robotics for Construction Sites

These robots have been used and are making a real difference on construction sites.

SAM100 (Semi-Automated Mason)

Developed by Construction Robotics, this robot can lay bricks six times faster than a human mason and has been deployed on projects across the U.S.

Hadrian X by FBR

This robot can lay 1,000 bricks an hour and has been used in residential and commercial construction projects in Australia.

Boston Dynamics’ Spot

This four-legged robot is used for site inspection, equipped with sensors and cameras to collect real-time data on construction progress.

Apis Cor

Known for 3D-printing entire homes, Apis Cor made headlines by constructing a fully functional home in less than 24 hours.

What the Future Holds for Construction Robotics

The construction technology landscape is changing rapidly, and construction robotics will play a more prominent role in the industry in the years to come.

This is what we can expect at the construction sites of the future:

Fully Autonomous Construction Sites

Construction robotics will enable fully autonomous construction sites, which, according to U.S. Bridge, will allow construction managers to deploy autonomous equipment without the need for human operators.

AI-Predictive Maintenance and Decision-Making

AI-enhanced construction technology will allow construction managers to better predict the lifespan of construction equipment and robotics, giving them the ability to make precise decisions about preventative repairs and regular maintenance.

Modular and Prefabricated Robotics-Aided Construction

Modular and prefabricated robotics-aided construction will streamline the process of creating modular and prefabricated structures, ultimately reducing the costs of these structures and minimizing errors within the construction process, which can lead to a higher quality end product.

Sustainability Enhancements

Construction robotics technology will not only help maximize efficiency on construction sites, but it will also improve sustainability. This advanced technology will enable sustainability enhancements throughout the entire construction process, from the beginning of the planning stages until the project is completed.

Construction Robotics Frequently Asked Questions

Will robots replace humans in the workforce?

No, robots will not replace human workers in construction. Instead, they will automate tedious, repetitive, or risky tasks, giving human workers the ability to take on advanced construction positions.

How does robotics help solve construction labor shortages?

Construction robotics can supplement the human workforce necessary for construction projects, helping to alleviate the strain of the ongoing shortage of skilled workers.

What types of robots are used in construction today?

A wide range of robots are used in construction today, including industrial robots, autonomous construction vehicles, drones, and humanoid laborers.

Are construction robots safe to work around?

Yes, in fact, construction robotics technology often improves the safety of the job site and protects workers by taking on some of the more dangerous tasks.

Future-Proof Your Construction Management Career at Texas A&M University

Advanced technology, including artificial intelligence and construction robotics, will continue to redefine the construction field in the years ahead. The online Master of Science in Construction Management degree at Texas A&M University is a multidisciplinary program that offers a curriculum anchored by traditional construction methods and enhanced by innovation. With an emphasis on critical thinking, processes, and construction technology, this industry-specific program equips graduates with the skills required to pursue leadership positions in construction management.